Sheet metals are essentially metals that are malleable and have been beaten into flat pieces of varied thickness. These can also be called metal plates. They are used in many industries, including aerospace, automotive, farming, etc. In this blog, Nowandlive will help you analyse what sheet metals are and how they can be supremely useful for your professional work. You can even check out the collection of sheet metals with Leroy Merlin.

What are Sheet Metals?

Sheet metals are metal pieces that have been rolled or beaten into thin sheets. Their thickness is generally less than 6.35 mm (0.25 inches). Their fabrication is quite a complex process that requires specialised skills and equipment. The products, however, are very essential in many industries. They are usually very light, robust and corrosion-resistant. They are also easy to produce in various shapes and are relatively inexpensive.

What are the Uses of Sheet Metals?

Sheet metals have found their way in many high end technical industries, so much so that most of the building processes cannot be completed without these sheets. Here are some important uses of sheet metals in different industries-

1. Automobile

Sheet metal is used to make car frames and is what most people refer to as the “body” of the vehicle. These sheet metal frames are needed to hold doors, seats and roofs in place. Sheet metal is used because it is durable and can withstand the forces experienced in an accident.

2. Construction

Sheet metal is also commonly used in construction projects to connect architectural and structural elements, allowing them to retain their shape. The metal cladding is used to cover large areas such as roofs or partitions. Sheet metal is also often used in combination with other materials to make walls, floors and ceilings.

3. Equestrian sports

The use of sheet metal is particularly decorative in nature. The equestrian industry typically uses sheet metal to create decorative breastplates and other equine equipment.

4. Aviation

Without sheet metal, airplanes wouldn’t fly far. In fact, most of the plane is covered with protective sheet metals. This is especially important for parts like wings and fuselage.

Types of Sheet Metals

| Type of metals | Characteristics |

| Aluminum | Lightweight, strong, corrosion-resistant, good conductor of heat and electricity |

| Steel | Strong, durable, relatively inexpensive,

|

| Copper | Good conductor of heat and electricity, resistant to corrosion, antimicrobial |

| Brass | Strong, durable, resistant to corrosion |

| Stainless steel | Very resistant to corrosion and rust, durable, good conductor of heat |

How are Sheet Metals transformed-

1. Laser cutting

Computer numerical control (CNC) uses a powerful laser beam to cut non-standard shapes from sheet metal. This process is very different from the traditional CNC cutting, which uses tools such as a milling cutter. It can simultaneously cut metals of different thicknesses all in a low temperature range. It can also help create detailed and complex designs.

2. Plasma cutting

This technique allows you to cut thicker sheets that a laser cannot penetrate. A jet of hot plasma is spewed on the surface of the metal in the shape of the desired design feeded in the computer. This method is good for simpler shades.

3. Bending

Once the cutting process is complete, the metal sheets can be bent into the desired shape. Bending involves fastening a sheet metal between an upper tool and a die mold. Several machines can perform this processlike manual press brakes, depending on the size and complexity.

4. Rivets

Rivets are small metal parts used to permanently join two or more metal sheets together. They are available in different sizes and materials and we always choose the right one for the desired design.

Rivets are inserted into holes that have already been cut or drilled in the sheet metal. A CNC riveter presses against the rivet head and the rivet body expands into a joint, sealing the two sheet metal parts together.

Top Picks For Sheet Metals-

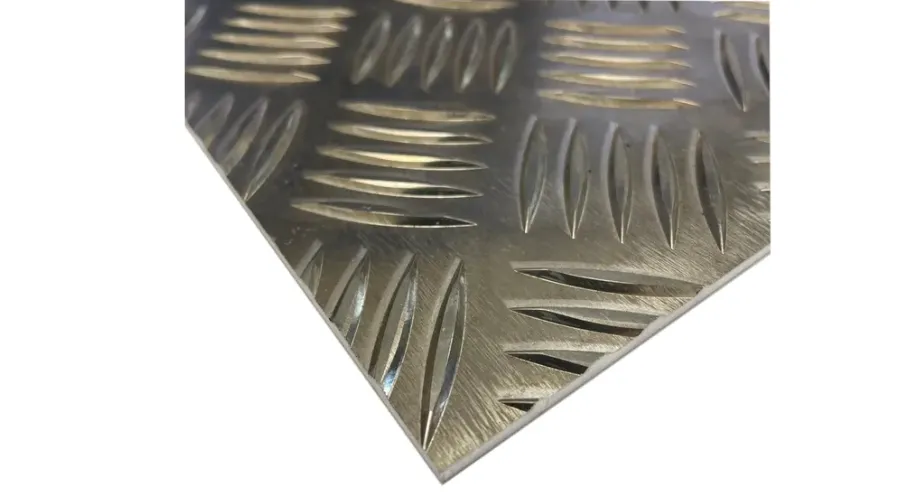

1. Polished Silver Checkerboard Aluminum Sheet

This Checkerboard Aluminum Sheet is a strong and durable plate that can be an easy conductor of electricity and can have many functions.

| Main material | Aluminium |

| Product finishing | Almondy |

| I wait | Polished |

| Colour | Silver |

| Thickness (in mm) | 3 |

| Minimum cutting length and width | 100, 100 |

| Maximum cutting length and width | 800, 1200 |

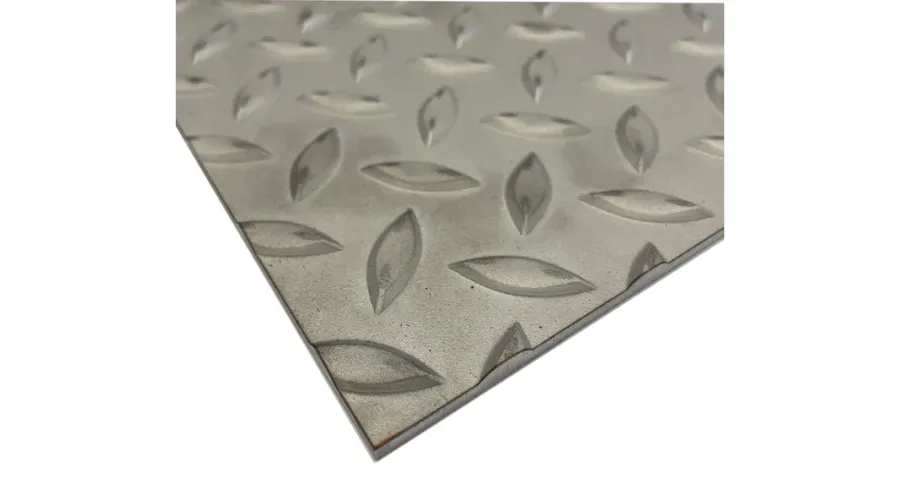

2. Matt Silver Checkerboard Stainless Steel Sheet

This Matt Silver Stainless Sheet can be easily cut into your desired shape. You can easily use a metal configurator to do the same.

| Main material | Stainless steel |

| Product finishing | Almondy |

| I wait | Opaque |

| Colour | Silver |

| Thickness (in mm) | 3 |

| Minimum cutting length and width | 100, 100 |

| Maximum cutting length and width | 800, 1200 |

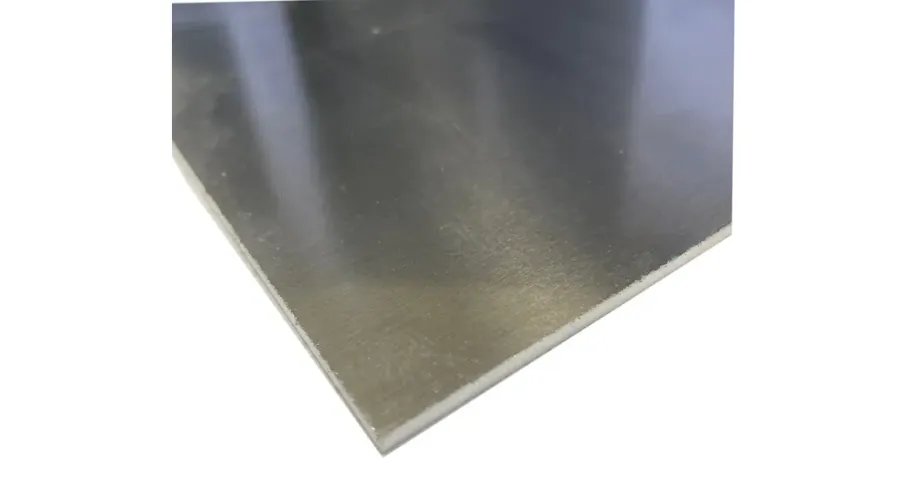

3. Aluminum Sheet Metal with a Smooth Shiny Grey Finish

This Aluminium sheet metal is 5 mm thick and can be an easy addition to your construction pile. It can easily be cut or welded to fit and fix your pieces.

| Main material | Aluminium |

| Product finishing | Smooth finish |

| I wait | Polished |

| Colour | Grey |

| Thickness (in mm) | 5 |

| Minimum cutting length and width | 100, 100 |

| Maximum cutting length and width | 800, 1200 |

Also, read- Top 5 Bathroom Furniture Trends For 2023 And More

Conclusion

Due to its wide range of uses in everyday life, sheet metal is one of the best-known and most important metals in mechanical engineering. Since it is found in cars, machines, house facades and furniture, sheet metal is widely used. This is particularly clear in areas earmarked for residential development. Head over to Leroy Merlin and check out these sheet metals recommended by Nowandlive. They are very sturdy and of high quality.